How to Conduct Routine Inspections on Aboveground Storage Tanks – API 653

Your Step-by-Step Guide to Conducting Monthly Routine Inspections on Storage Tanks

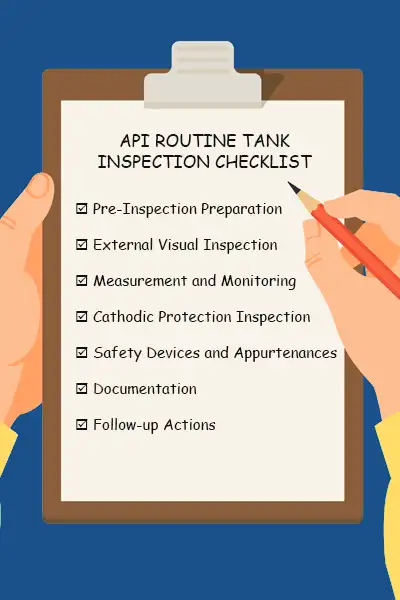

In addition to formal external and internal inspections, the API 653 standard provides guidelines for routine inspections of large above-ground storage tanks (ASTs). These in-service examinations should be done on a monthly basis and can be conducted by the tank owner or operator.

In this article, we will delve into the details of conducting monthly routine inspections on ASTs, following the guidelines provided by API 653. That’s the standard published by the American Petroleum Institute (API) that applies to above-ground storage tanks that are field-erected or field-built, have a diameter of 30 feet or more or a height of 50 feet or more, and have a capacity typically greater than 75,000 gallons.

Monthly routine inspections serve as a proactive measure to monitor the condition of aboveground storage tanks, identify emerging issues, and prevent potential failures. These inspections primarily involve visual examinations, measurements, and checks of critical components. Let’s take a look at each step.

Step 1: Pre-Inspection Preparation

Before initiating the monthly routine inspection, you will need to gather the necessary tools and equipment, such as a clipboard, measuring tape, flashlight, camera, and appropriate personal protective equipment (PPE). Additionally, familiarize yourself with the tank's design specifications, previous inspection reports, and any relevant maintenance records.

Step 2: External Visual Inspection

Commence the inspection by visually examining the tank's external surfaces. Look for signs of corrosion, leakage, coating deterioration, uneven settlement, or any visible abnormalities. Pay special attention to welds, joints, appurtenances (vents, gauges, fittings), and potential damage caused by external factors such as weather or external forces.

Step 3: Measurement and Monitoring

Measurements are essential to assess the tank's condition accurately. Utilize a measuring tape or appropriate instruments to perform the following measurements:

- Shell Verticality: Measure the verticality of the tank's shell by taking readings at various points around the circumference. Deviations from the tank's vertical alignment could indicate structural issues or settlement.

- Settlement: Monitor and measure any settlement or movement of the tank's foundation. Use reference points or leveling instruments to detect changes and record the measurements for comparison with previous inspections.

- Out-of-Roundness: Assess the tank's roundness by measuring the circumference at several levels. Any significant deviations from the tank's designed roundness may indicate bulging or deformation.

Step 4: Cathodic Protection Inspection

For tanks equipped with cathodic protection systems, evaluate the effectiveness of the system during monthly inspections. This inspection involves checking sacrificial anodes or impressed current systems for proper operation and ensuring they are adequately protecting against corrosion.

Make sure sacrificial anodes are present, securely attached, and in good condition. If anodes are significantly depleted or damaged, they may need to be replaced to maintain effective corrosion protection.

When checking impressed current systems, make sure the power supply is functioning correctly, the anodes are intact, and the system is effectively providing the required protective current.

Step 5: Safety Devices and Appurtenances

Inspect and test all safety devices and appurtenances associated with the tank. This includes pressure relief valves, emergency vents, flame arresters, and other critical components. Ensure that these devices are functioning correctly and have not been damaged or compromised.

Inspect and test all safety devices and appurtenances associated with the tank. This includes pressure relief valves, emergency vents, flame arresters, and other critical components. Ensure that these devices are functioning correctly and have not been damaged or compromised.

Step 6: Documentation

Accurate and thorough documentation is vital for maintaining a comprehensive inspection history. Record all findings, measurements, observations, and any necessary corrective actions. Include photographs or sketches to provide visual evidence and facilitate future comparisons. Retain previous inspection reports for reference and trend analysis.

Step 7: Follow-up Actions

After completing the inspection, carefully review the findings and determine any necessary follow-up actions. Address identified issues promptly to prevent potential escalation. Depending on the severity of the findings, these actions may range from scheduling repairs or maintenance to consulting with a qualified engineer or tank specialist for further assessment.

To review, monthly routine inspections are an integral part of maintaining the integrity and reliability of storage tanks. By adhering to the recommendations provided by API 653 and implementing a diligent inspection program, tank operators can detect and address issues before they escalate into more significant problems. Therefore, it’s important to prioritize proactive maintenance and inspections to minimize the risk of tank failures, mitigate environmental hazards, and ensure the longevity of your storage tanks.

While this guide provides a good overview for conducting monthly routine inspections, you may need to consult the API 653 standard directly for specific guidelines tailored to your tank's design, operating conditions, and industry requirements. Additionally, local regulations should be considered when developing your inspection program.

If you have any specific questions or concerns regarding tank inspections, maintenance, or industry standards, it is always advisable to seek guidance from qualified professionals or organizations with expertise in the field.

-- Genesis Environmental Solutions provides API 653 and STI SP001 storage tank inspections throughout Illinois, Iowa, Kansas, Missouri, Nebraska and Oklahoma. We provide AST services for all types of tanks, including fuel oil tanks. All work is carefully documented and compliant with federal, state and local regulations. Contact us today for more information.